IN FOCUS: DIGITAL SOLUTIONS

Ready for the future

As a technology leader for trenchless contruction, the demands on our own products are high. This goes as well for digitalisation, with TRACTO leading the market for innovative steerable drilling rigs.

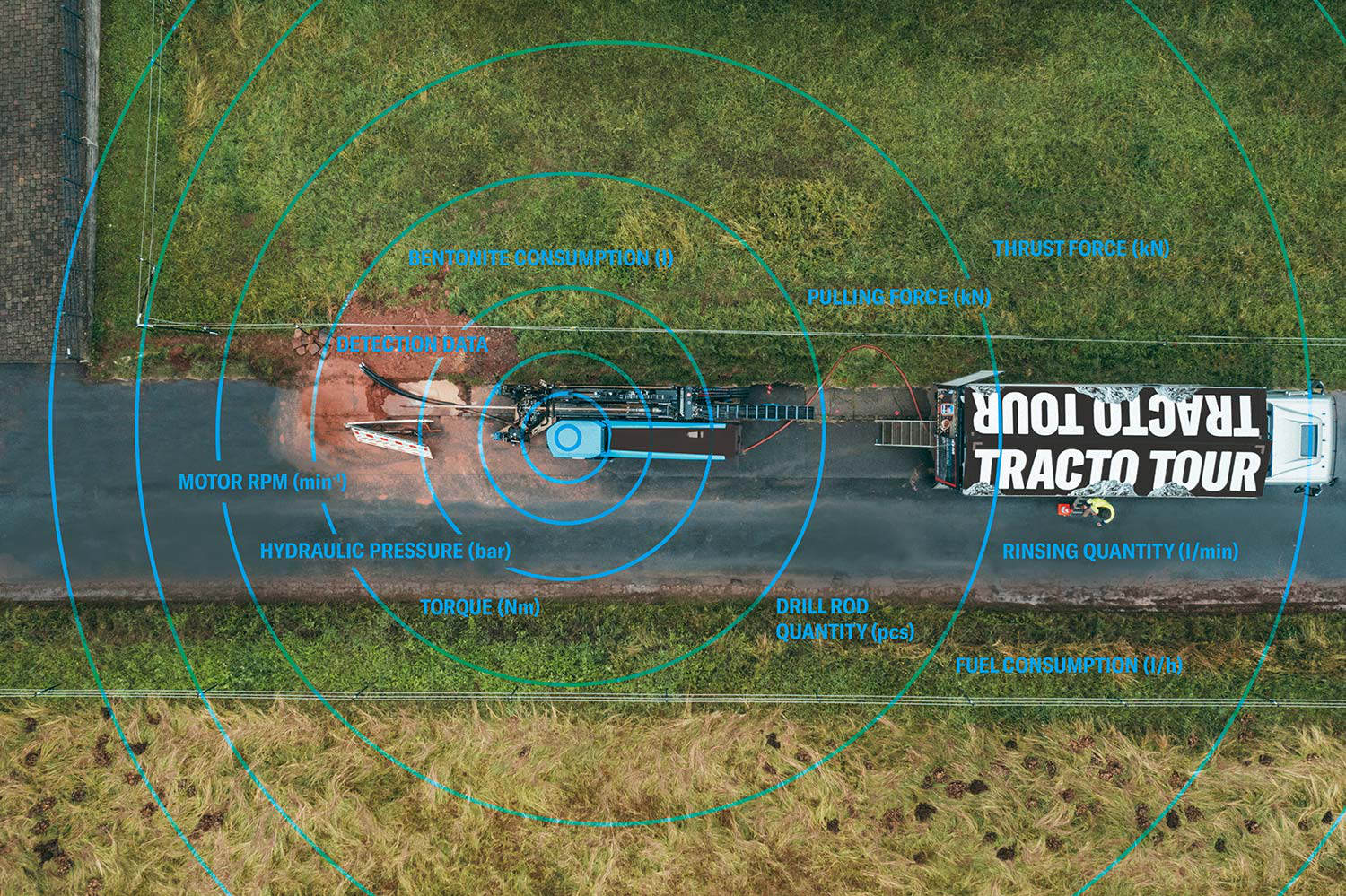

As a technology leader for trenchless contruction, the demands on our own products are high. This goes as well for digitalisation, with TRACTO leading the market for innovative steerable drilling rigs. Due to an extremely high degree of automation and a sophisticated steering concept, the latest GRUNDODRILL generation even allows remote steerable drilling and the integration of the DCI detection display. Intelligent interconnection of the drilling rigs with cloud-based software solutions makes planning, execution, documentation and invoicing of a steerable bore even more efficient.

The “Cockpit“ software visualises data relevant for the performance of the GRUNDODRILL rigs and records them centrally. This helps to identify problems on time, guaranteeing a smooth working process at the jobsite. By recording the consumption data, potential savings can be determined. The clever software is not only available for the latest generation of HDD rigs from TRACTO, but for all GRUNDODRILL rigs from year of construction 2021 onwards.

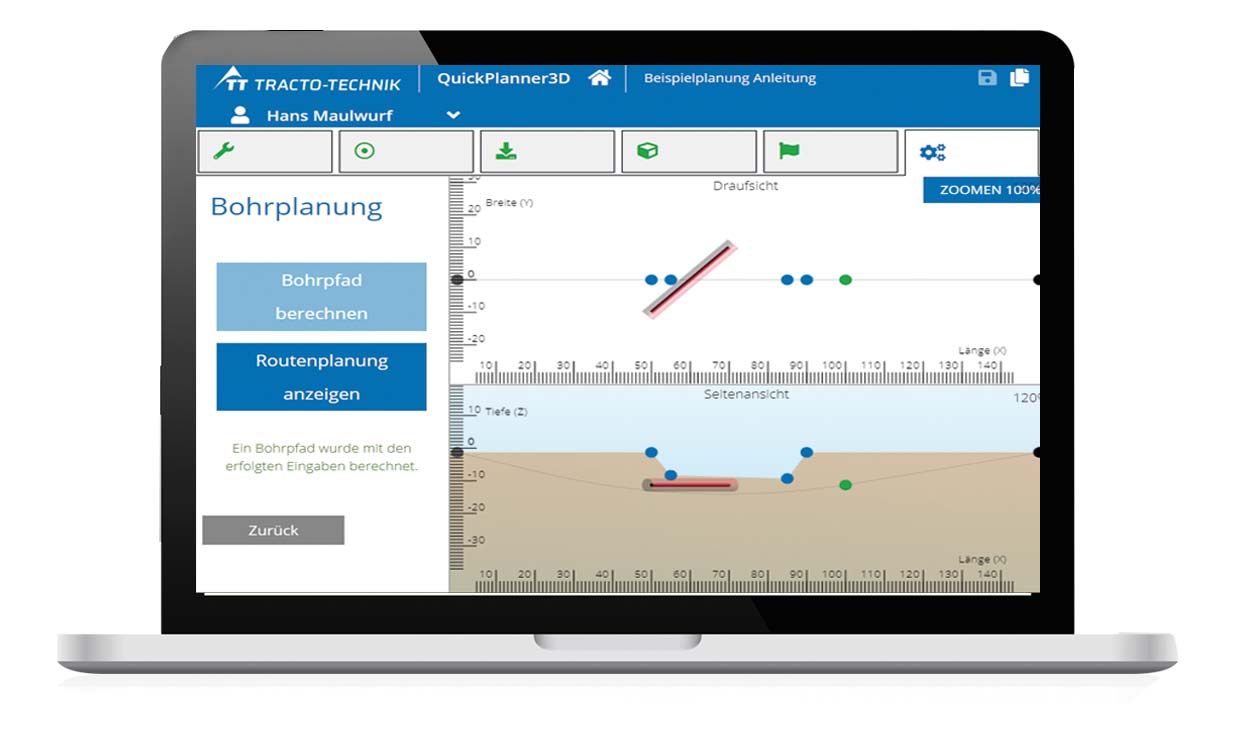

It’s not just the drilling rigs which are digitally up to date at TRACTO. With the “QuickPlanner3D” software, bore paths can be automatically planned three-dimensionally in just a few steps. The software was developed in close cooperation with HDD experts and can be used on any internet-compatible PC.

It’s not just the drilling rigs which are digitally up to date at TRACTO. With the “QuickPlanner3D” software, bore paths can be automatically planned three-dimensionally in just a few steps. The software was developed in close cooperation with HDD experts and can be used on any internet-compatible PC.

Digital Products

With the easy-to-use QuickPlanner3D, professionals and even unexperienced users are able to plan the most complicated bore paths quickly and precisely. That way users can carry out their HDD jobs in an even safer and more profitable way.