in focus potential: Future job potential – house connections

FUTURE

POTENTIAL

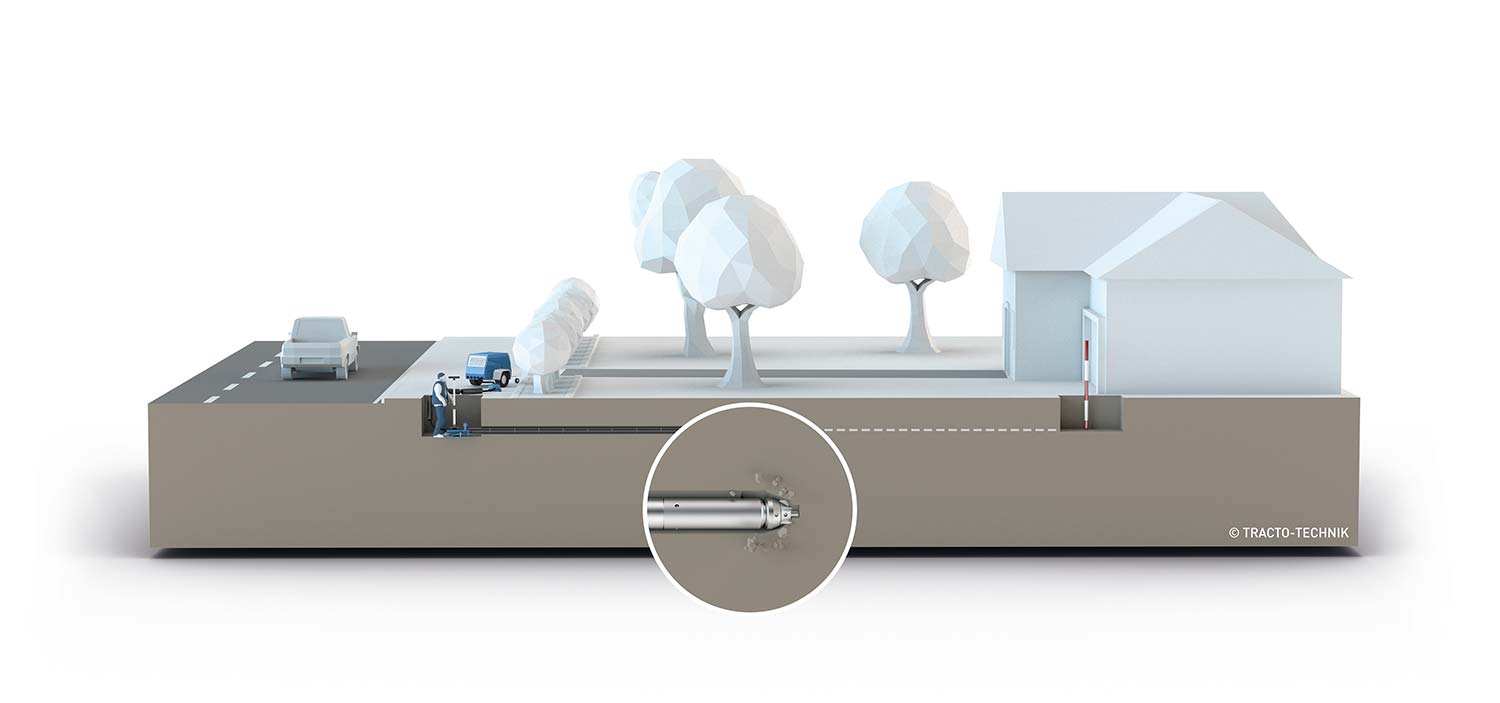

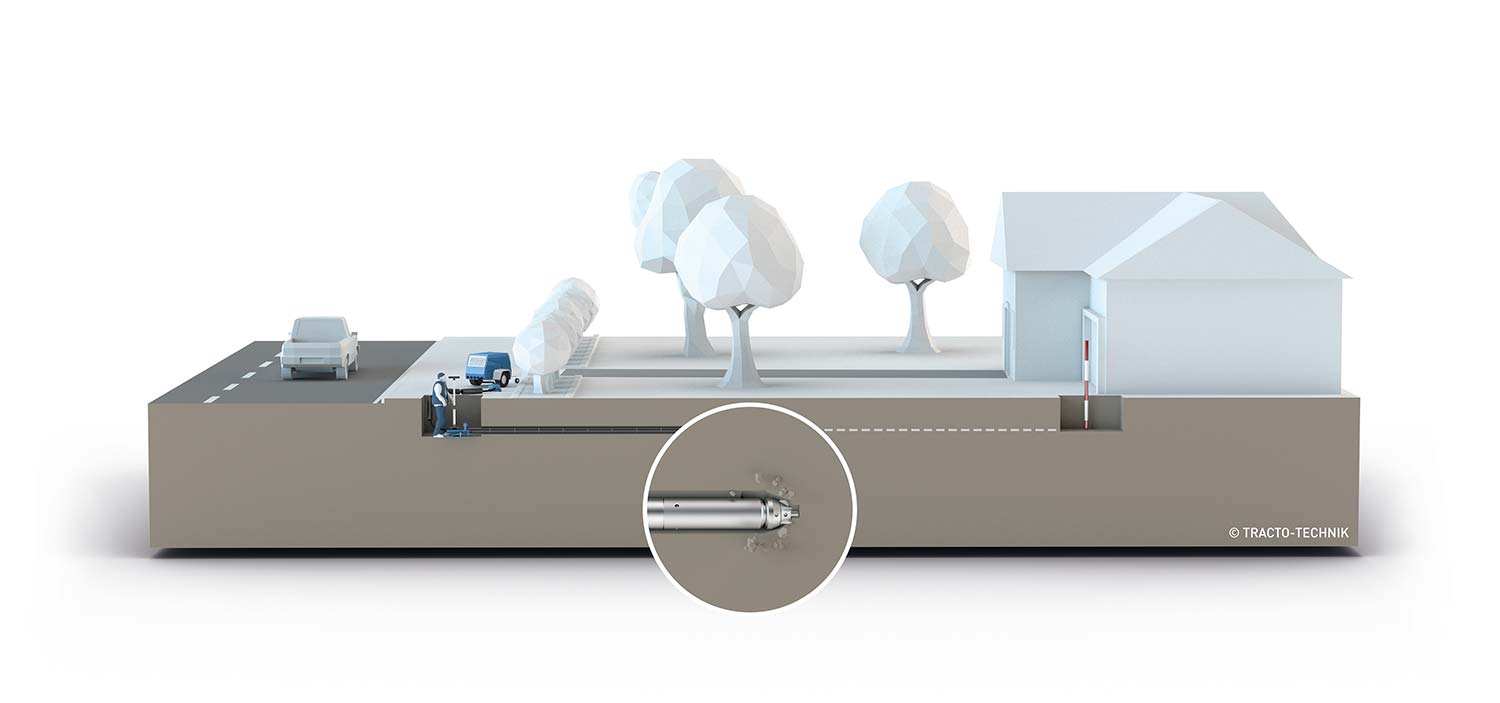

House connections completely trenchless using TRACTO technology

POTENTIAL

There are many good reasons to invest in trenchless technology as a civil engineering company. Not only because it is innovative, sustainable and resource-friendly. Underground pipe and cable installation is the future technology, which can meet the demands of citizens, network operators, municipalities and the environment. Because the NODIG technology has advanced in line with the requirements and is more versatile than ever today. Especially with house connection technolgy there is a great potential for contractors.

Grants create incentives for new house connections

Everyone is talking about sustainability and the sustainable use of energy is now incorporated into many laws. The introduction of a CO2 tax or other fees on oil and gas nowadays increases the costs for homeowners. At the same time, specific sustainable systems are required, e.g., the installation of new heating systems using renewable energies. In many countries homeowners receive special grants from the state and suppliers to make the changeover attractive. The interaction of government fundings and the introduction of CO2 taxes creates new potential for the construction industry with regard to house connections. In Germany, the legal recommendation for central-heating boilers to be replaced after 20 years at the latest promotes the switch to new connections. The figures speak volumes: The German Federal Association of Chimney Sweepers states that 3 million oil heating and 4 million gas heating systems are in operation for more than 20 years. There is also a big incentive here through grants to switch to renewable energy.

Grants create incentives for new house connections

Everyone is talking about sustainability and the sustainable use of energy is now incorporated into many laws. The introduction of a CO2 tax or other fees on oil and gas nowadays increases the costs for homeowners. At the same time, specific sustainable systems are required, e.g., the installation of new heating systems using renewable energies. In many countries homeowners receive special grants from the state and suppliers to make the changeover attractive. The interaction of government fundings and the introduction of CO2 taxes creates new potential for the construction industry with regard to house connections. In Germany, the legal recommendation for central-heating boilers to be replaced after 20 years at the latest promotes the switch to new connections. The figures speak volumes: The German Federal Association of Chimney Sweepers states that 3 million oil heating and 4 million gas heating systems are in operation for more than 20 years. There is also a big incentive here through grants to switch to renewable energy.

And then there is the fibre optics expansion. In Germany, for example, municipalities, regional authorities as well as publicly owned companies can apply for funding via the so-called “Grey Areas” scheme for regions where the download speed is less than 100 Mbit/s. The federal government is making available a total of 12 billion euros for the fibre optic connections, the federal states are contributing to the costs. Similar funding is available in other countries.

House connections completely trenchless using TRACTO technology

Financial support is one thing, the actual installation of all those new house connections is another. Because the costs for installing the service lines using open trench methods can quickly get out of hand. Not to mention the duration, noise, dirt and damage to the surface. Only good that there is the sustainable and resource-saving trenchless method, which considerably reduces load pollution, time and costs for the installation of new house connections for suppliers and homeowners. As a pioneer of NODIG technology, TRACTO offers solutions for all typers of house connections - from the house to the main line or vice versa - completely trenchless and without head access holes in front of the building!

The GRUNDOMAT displacement hammer is the perfect machine for starting with trenchless technology and the all-rounder for house connections with a straight bore path. Due to pinpoint 2-stroke thrust and movable head, it stays on track, even in stony soils. And for flexible routes, such as in rough terrains, the steerable GRUNDOPIT mini HDD systems are used – either from out of a pit, a manhole or a keyhole. With both the service pipe can be installed directly into the building through a core bore in the wall. With the GRUNDOMAT this is also possible in the opposite direction, i.e. from out of building to the main line. Special sealing ensures that the wall of the house is completely tight again afterwards.

Trenchless is standard today for well set-up companies

In order to highlight the potential for trenchless house connections from the client's and cotractor's perspective, we talked to Marius Schaefer from the network operator NGD Düsseldorf and to civil engineering cotractor Oliver Pöllmann. The utility company and the contractor are applying trenchless technology for many years.

As a representative of the sole energy and water supplier in the metropolis of Düsseldorf, Marius Schaefer sees trenchless technology “as standard for well set-up companies today”. The expert for grid connection technology says that there's increased planning effort for trenchless methods, which is yet outweighed by the savings in time, staff members and material.

NGD Düsseldorf even develops individual trenchless solutions for installing new house connections in their supply area in cooperation with TRACTO.

The GRUNDOMAT displacement hammer is the perfect machine for starting with trenchless technology and the all-rounder for house connections with a straight bore path. Due to pinpoint 2-stroke thrust and movable head, it stays on track, even in stony soils. And for flexible routes, such as in rough terrains, the steerable GRUNDOPIT mini HDD systems are used – either from out of a pit, a manhole or a keyhole. With both the service pipe can be installed directly into the building through a core bore in the wall. With the GRUNDOMAT this is also possible in the opposite direction, i.e. from out of building to the main line. Special sealing ensures that the wall of the house is completely tight again afterwards.

Trenchless is standard today for well set-up companies

In order to highlight the potential for trenchless house connections from the client's and cotractor's perspective, we talked to Marius Schaefer from the network operator NGD Düsseldorf and to civil engineering cotractor Oliver Pöllmann. The utility company and the contractor are applying trenchless technology for many years.

As a representative of the sole energy and water supplier in the metropolis of Düsseldorf, Marius Schaefer sees trenchless technology “as standard for well set-up companies today”. The expert for grid connection technology says that there's increased planning effort for trenchless methods, which is yet outweighed by the savings in time, staff members and material.

NGD Düsseldorf even develops individual trenchless solutions for installing new house connections in their supply area in cooperation with TRACTO.

Contractor Oliver Pöllmann considers the GRUNDOMAT as a “must-have for every construction company, even if it is only used for five applications a year” and highlights that the feedback from homeowners on trenchless construction is extremely positive. While he also uses the GRUNDOMAT in series, the contractor uses his GRUNDOPIT for “individually tailored, single connections.” Even though the preparation for steerable bores is more complex than for a soil displacement hammer application, adds the professional. “The reward that you get for an quote that has no alternative is quite impressive”, says Oliver Pöllmann with a grin.

Interviews

Interview with Oliver Pöllmann

Oliver Pöllmann GmbH is a small, innovative civil engineering company from the Rhineland area in central Germany, who have numerous customers in this region. Managing Director Oliver Pöllmann is the second generation to run the family business and is well aware of the imponderables of the industry. The company’s machinery includes NODIG systems from TRACTO for steerable and non-steerable methods, which are of course also applied for house connections.

Mr. Pöllmann, you have been using the trenchless technology for some time now, even for house connections. Which fields of supply show the greatest demand for new house connections in your operational area?

The demand is particularly high for internet expansions. For simple fibre-optic house connections, we use GRUNDOMAT soil displacement hammers, which we have been employing since the 1980’s. For more complicated and/or longer connections we have a GRUNDOPIT at hand. Connections for gas, water and sewage are usually individual contracts nowadays. Here it is important to be quick and ready for action at any time on these jobsites. The rule here is: the more specialised the task, the more lucrative for the contractor.

How has the response from homeowners been, who have received a trenchless house connection? There are still concerns among the public that the underground bores are not accurate or that leakages can occur at the entry point of the building. Also, what are your experiences with public clients, such as utility companies or municipalities in this context?

The response from homeowners has been positive throughout. They are amazed to see how fast the work is completed without causing any damage whatsoever to their gardens. Sometimes, after work is done, I have to justify the price for it, but I simply explain the whole package including purchase costs and the preparation involved, as well as the follow-up time, which the customer does not see. Of course, I make it clear that with trenchless installations, no costs for demolition and reinstatement are necessary and all the noise and dirt involved with open trenching is omitted. With experienced drillers and the appropriate technology, precise drilling is virtually guaranteed. Up to now I have not made a bore directly into a cellar, but there are certified building entries this (e.g. from Hauff).

Public clients demand trenchless installations if they are familiar with these tasks. If they aren’t – surprisingly, quite a few sewage companies for instance – they are amazed to see what is possible nowadays. We have the great advantage of owning two GRUNDOBORE BM 200 and BM400 auger bore rigs and also a GRUNDOPIT PS60 mini HDD rig. Therefore, we really have the complete range of small size bore rigs and can always provide the optimal application for each respective jobsite.

Mr. Pöllmann, you have been using the trenchless technology for some time now, even for house connections. Which fields of supply show the greatest demand for new house connections in your operational area?

The demand is particularly high for internet expansions. For simple fibre-optic house connections, we use GRUNDOMAT soil displacement hammers, which we have been employing since the 1980’s. For more complicated and/or longer connections we have a GRUNDOPIT at hand. Connections for gas, water and sewage are usually individual contracts nowadays. Here it is important to be quick and ready for action at any time on these jobsites. The rule here is: the more specialised the task, the more lucrative for the contractor.

How has the response from homeowners been, who have received a trenchless house connection? There are still concerns among the public that the underground bores are not accurate or that leakages can occur at the entry point of the building. Also, what are your experiences with public clients, such as utility companies or municipalities in this context?

The response from homeowners has been positive throughout. They are amazed to see how fast the work is completed without causing any damage whatsoever to their gardens. Sometimes, after work is done, I have to justify the price for it, but I simply explain the whole package including purchase costs and the preparation involved, as well as the follow-up time, which the customer does not see. Of course, I make it clear that with trenchless installations, no costs for demolition and reinstatement are necessary and all the noise and dirt involved with open trenching is omitted. With experienced drillers and the appropriate technology, precise drilling is virtually guaranteed. Up to now I have not made a bore directly into a cellar, but there are certified building entries this (e.g. from Hauff).

Public clients demand trenchless installations if they are familiar with these tasks. If they aren’t – surprisingly, quite a few sewage companies for instance – they are amazed to see what is possible nowadays. We have the great advantage of owning two GRUNDOBORE BM 200 and BM400 auger bore rigs and also a GRUNDOPIT PS60 mini HDD rig. Therefore, we really have the complete range of small size bore rigs and can always provide the optimal application for each respective jobsite.

You apply GRUNDOMAT soil displacement hammers, as well as GRUNDOPIT mini HDD rigs for house connections. How would you rate the machine technology in view of quality, efficiency and productivity?

The soil displacement hammer is simply a must for all civil engineering companies, even if you only have about five applications per year. You also have low personnel requirements, as it can be operated by just one person. The GRUNDOMAT is the Mercedes of all soil displacement hammers. Competitors have been catching up over the years, but the sales team at TRACTO is also the best you can find. There is one time I remember, when I ordered an extension sleeve for a pull-in cable. Due to a transmission error, the spare part had still not arrived two days after ordering, but I needed it desperately. I called my contact at the customer centre in Viernheim and was really ranting and raving at him. He then got into his car and brought the sleeve (9,90 € NET!) to our jobsite. Since that day, I know where I stand with TRACTO. They are there when I need them. Conclusion: priceless!

Like I said, the GRUNDOMAT is perfect for simple bore tasks and is particularly worthwhile for serial applications, e.g., for annual contracts with utility companies. You can’t compare the soil displacement hammer to GRUNDOPIT, because the first priority is the price – per metre or quantity of house connections. Therefore, the mini HDD rig is only applied, where a soil displacement hammer can’t go. Which in turn also means that a single price (flat rate) is negotiated for each individual GRUNDOPIT contract. For an annual contract with a utility company this wouldn’t make sense, as they calculate with soil displacement hammers. The GRUNDOPIT needs tasks specially tailored to its capabilities: road, stream or house crossings for internet, electricity, gas, water or sewage. It needs two operators, who are trained and enjoy trying out something new. Then it is possible to master even the most complicated bore paths with the steerable mini drilling rig. And the purchase must first pay for itself. However, the reward you get for an offer with no alternative really is impressive.

How do you assess the potential of trenchless house connection technology from the perspective of a civil engineering contractor? How big are the competitive advantages compared to companies who only offer open trench installations?

There is no getting around trenchless technology today. The only question is: which contractor has the better trenchless systems? If you invest in reliable machines, you can actually earn good money. So, a big thank you to TRACTO! You have developed some fantastic equipment.

Mr. Pöllmann, many thanks for a truly enlightening conversation!

You can find out more about the Pöllmann company at

www.poellmann-gmbh.de

Interview with Marius Schaefer

The Network Association Düsseldorf mbH, a wholly owned subsidiary of municipal utilities of the city of Düsseldorf, operates the distribution network for electricity, natural gas, water and district heating, as well as the water distribution network in the region and is responsible for the maintenance and expansion of the pipeline network infrastructure. This comprises a 6,556 km long electricity network, 2,014 km of natural gas pipelines, 2,562 km of water network and 250 km of district heating pipelines including the respective house connections. Marius Schaefer, a graduate engineer, is responsible there for the network connections.

Mr. Schäfer, where do you see special challenges and possible applications for trenchless technology, especially in the house connection field?

We see the most frequent challenge in irregular overbuilding or planting above network connections on private properties. Using the trenchless technology, conflicts can be eliminated and avoided in advance. Another aspect is the fact we can work much faster and traffic is less affected. However, the use of trenchless technology needs to be planned more elaborately in advance.

The Network Association Düsseldorf has been using the trenchless technology for almost a decade. We apply soil displacement hammers and also HDD rigs for steerable bores. This technology has proven very successful due to the well conceived approach of our specialists.

How do you rate the potential of trenchless technology? Could more house connections be carried out in shorter time, if trenchless technology was applied more often?

Nowadays, trenchless technology is the standard for well-positioned companies. Even if the planning effort, as described earlier, appears to be considerably more complex than with the conventional technology. The arguments for saving resources speak for themselves. Conclusion: We save time, personnel and material costs.

I really can’t say anything about the expansion applications, because I simply don’t have the knowledge. In our upcoming projects, we will only create a “head hole” on the supply line for the installation of new connections using the HDD technology by applying a special drill crown and a new type of building entry. In compliance with the DVGW* regulations, we will create new network connections beneath a ground plate at an approx. 1,20 m horizontal offset to the existing service lines.

*(A recognised standardisation body for the gas and water industry in Germany)

Many thanks for these interesting insights, Mr. Schaefer!