IN FOCUS Product: GRUNDOSTEER

DIRECTIONALLY

SIMPLE

May we introduce you to: The new GRUNDOSTEER with locatable head for directional corrections during the static process.

GRUNDOSTEER is the latest addition to the TRACTO product family. The guided rod pusher complements our product range with an easy-to-operate device that, in terms of installation method, is located between the GRUNDOMAT soil displacement hammer and the GRUNDOPIT mini fluid-assisted drilling rigs. The official method definition is: “The guided rod pusher is a static, correctable method for the production of house connections, as well as for the installation of product pipes or protection pipes underneath roads or railway tracks.”

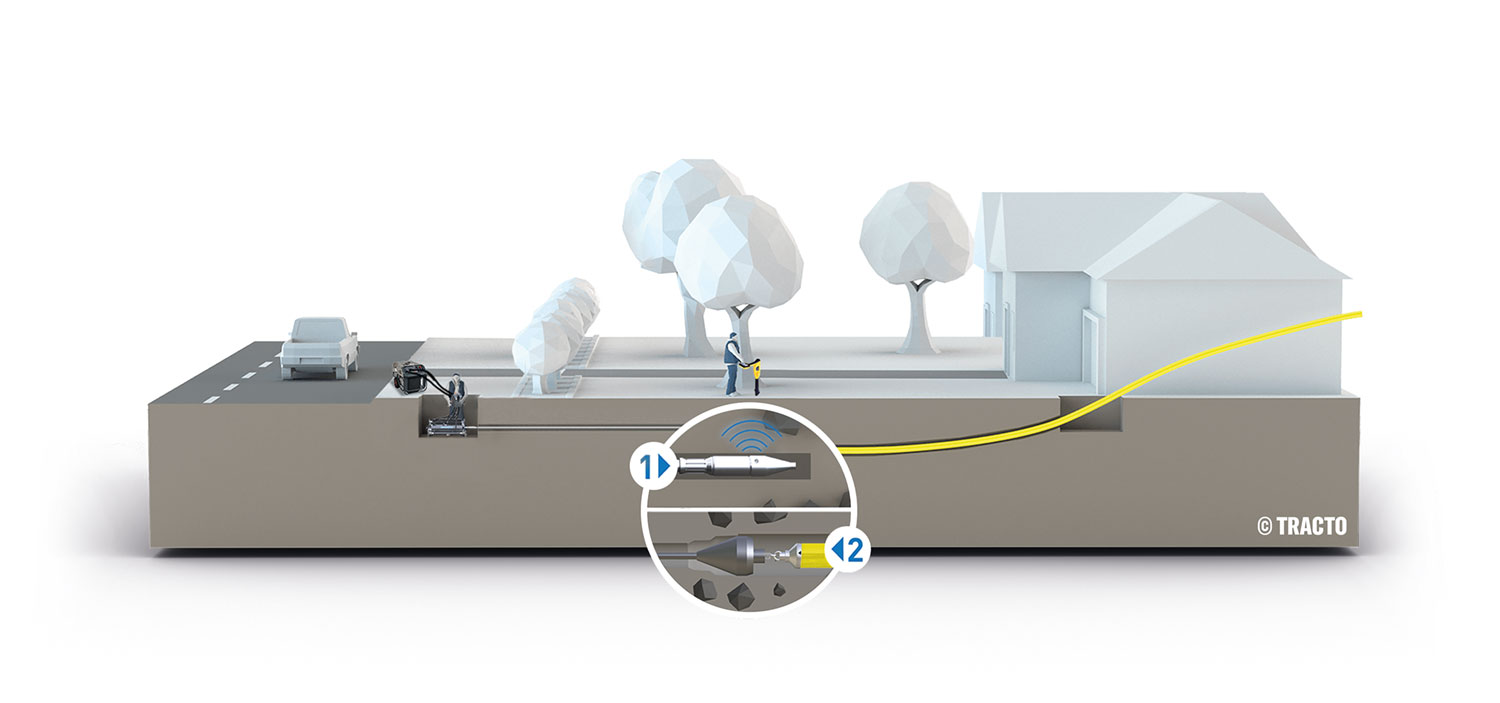

What may sound abstract, is easily explained. As with the HDD method, the GRUNDOSTEER is first used to create a pilot bore along the planned bore path. In the process, the locatable guiding head is tracked above ground with a locating device, indicating any deviations from the intended bore path. If directional corrections are necessary, the position of the guiding head can be easily read off a time scale on the rods’ position connector and changed by rotation in the desired direction. Upon arrival in the target pit, the head is replaced by an expander enlarging the bore path to the diameter of the pipe attached as it is pulled back. Unlike the HDD method, no drilling fluid is required when applying the guided rod pusher.

What may sound abstract, is easily explained. As with the HDD method, the GRUNDOSTEER is first used to create a pilot bore along the planned bore path. In the process, the locatable guiding head is tracked above ground with a locating device, indicating any deviations from the intended bore path. If directional corrections are necessary, the position of the guiding head can be easily read off a time scale on the rods’ position connector and changed by rotation in the desired direction. Upon arrival in the target pit, the head is replaced by an expander enlarging the bore path to the diameter of the pipe attached as it is pulled back. Unlike the HDD method, no drilling fluid is required when applying the guided rod pusher.

Bridge to the HDD method

The key to the accuracy of the GRUNDOSTEER rod pusher is the head. Its position is constantly controlled by the built-in transmitter via a detection device during the static process. Its slightly slanted shape allows directional correction. To do this, the position of the so-called “steering head” is simply read off a time scale on the position connector of the drill rods and, if necessary, corrected by rotating it in the desired direction. Through this combination of static soil displacement and simple correctability of the drilling direction, the GRUNDOSTEER forms a bridge between the non-steerable soil displacement hammers and the steerable HDD flush drilling rigs. Thanks to the simple, but very reliable, steering principle and the easy directional correction, even less experienced operators can accurately establish house connections or short undercrossings using this method and easily gain first experiences with correctable methods.

The key to the accuracy of the GRUNDOSTEER rod pusher is the head. Its position is constantly controlled by the built-in transmitter via a detection device during the static process. Its slightly slanted shape allows directional correction. To do this, the position of the so-called “steering head” is simply read off a time scale on the position connector of the drill rods and, if necessary, corrected by rotating it in the desired direction. Through this combination of static soil displacement and simple correctability of the drilling direction, the GRUNDOSTEER forms a bridge between the non-steerable soil displacement hammers and the steerable HDD flush drilling rigs. Thanks to the simple, but very reliable, steering principle and the easy directional correction, even less experienced operators can accurately establish house connections or short undercrossings using this method and easily gain first experiences with correctable methods.

Inexpensive starter model in TRACTO quality

Getting started with the correctable trenchless rod pushing method is easy in many respects. On the one hand, the handling of the GRUNDOSTEER is conceivably simple and designed for high operating comfort. For example, the specially designed SIMCON® rods are not elaborately screwed together, but firmly connected via the simple bolt connection. The height adjustable control panel can be flexibly mounted at various positions on the machine frame and be optimally adapted to the height of the machine operator, enabling him to work comfortably in a standing position, while the thrust speed is regulated by a smooth-running hand lever.

Getting started with the correctable trenchless rod pushing method is easy in many respects. On the one hand, the handling of the GRUNDOSTEER is conceivably simple and designed for high operating comfort. For example, the specially designed SIMCON® rods are not elaborately screwed together, but firmly connected via the simple bolt connection. The height adjustable control panel can be flexibly mounted at various positions on the machine frame and be optimally adapted to the height of the machine operator, enabling him to work comfortably in a standing position, while the thrust speed is regulated by a smooth-running hand lever.

On the other hand, the necessary capital expenditure for the GRUNDOSTEER is very low. For example, operators who already own soil displacement hammers can use their GRUNDOCOPE aiming frames to align the GRUNDOSTEER. The fact there is no need for costly drilling fluid during rod pushing and only a simple locating device is required for checking the direction, have a further positive impact in terms of costs. Furthermore, the sturdy construction of the GRUNDOSTEER in proven TRACTO quality also pays off quickly.

Optimal, not only for house connections

The GRUNDOSTEER is ideal for short undercrossings in dense infrastructures without much effort and for quickly and easily establishing house connections of any kind. At just 1 m in length and 80 cm in width, the very compact rig can work from out of a pit towards the building or from the building through a core bore in the house wall.

Optimal, not only for house connections

The GRUNDOSTEER is ideal for short undercrossings in dense infrastructures without much effort and for quickly and easily establishing house connections of any kind. At just 1 m in length and 80 cm in width, the very compact rig can work from out of a pit towards the building or from the building through a core bore in the house wall.

An impressive total of 130 kN is available for rod pushing and pulling in the pipes up to an outer diameter of 100 mm, giving the guided rod pusher its type designation PS130.

The ‘PS 130’ has successfully proven its reliability in initial jobsite tasks at home and abroad. Near Paris, for example, it was used to safely install a ND 25 HDPE drinking water pipeline through a dense pipe network beneath the entrance hall of a building. The client Veolia, who supplies drinking water to 4.6 million people in the Paris region, was totally satisfied.

If you, as a user, would also like to test the GRUNDOSTEER on one of your projects, please simply contact the TRACTO sales representative, responsible for your region.

The ‘PS 130’ has successfully proven its reliability in initial jobsite tasks at home and abroad. Near Paris, for example, it was used to safely install a ND 25 HDPE drinking water pipeline through a dense pipe network beneath the entrance hall of a building. The client Veolia, who supplies drinking water to 4.6 million people in the Paris region, was totally satisfied.

If you, as a user, would also like to test the GRUNDOSTEER on one of your projects, please simply contact the TRACTO sales representative, responsible for your region.