IN FOCUS: GRUNDOBURST PROCESS ENGINEERING

„SUPER”

CLOSE-FIT

CLOSE-FIT

PIPE REHABILITATION USING THE REDUCTION METHOD WITH GRUNDOBURST

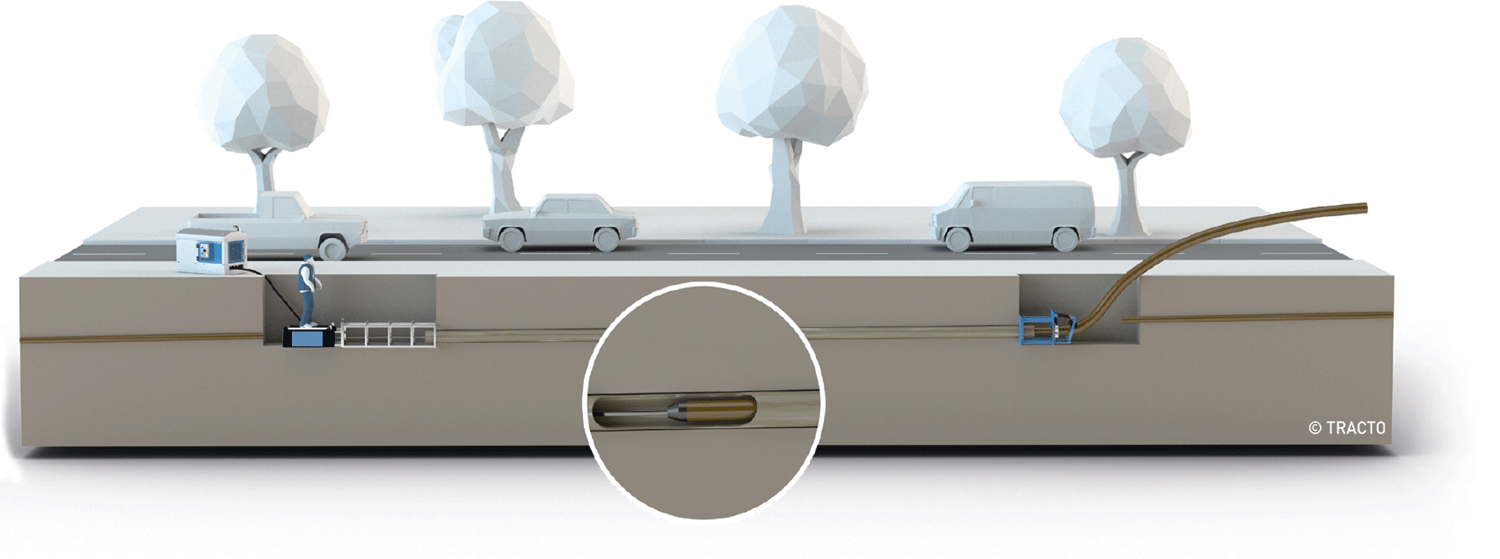

GRUNDOBURST systems from TRACTO are the all-rounders for pipe rehabilitation. The powerful pulling rigs can be used not only to renew damaged pipelines of the same or larger diameter without trenching, but also to renovate pipelines with smaller diameters. A particularly sustainable method of repairing damaged pipelines, when pipe bursting is out of the question, is the pipe reduction method.

Pipe reduction is one of the close-fit methods by which a damaged pipeline is rehabilitated by lining it with a new PE pipe without leaving a gap between the old and new pipe, known as an annulus. The method is particularly suitable for the trenchless rehabilitation of gas, water and wastewater pipes up to ND 1,200 that have been damaged by leaks, cracks, mechanical wear or corrosion. The installation of the self-supporting new pipe completely restores the statics and function of the pipeline to be rehabilitated. Its hydraulic capacity is only reduced by the wall thickness of the new pipe.

The basic principle of the reduction method is based on the possibility of reducing the diameter of the new pipe by hydraulic pulling to such an extent that it can be pulled into the interior of an old pipe of the same diameter. This is done by pulling the pipe string under constant tension through a reduction die which briefly reduces the pipe's cross-section by 10 % to 12 %. When the tension is released, the new pipe expands back to its original diameter and fits tightly against the inner wall of the old pipe. There is no annular space or annular gap, so the old and new pipes now have a "super" close-fit.

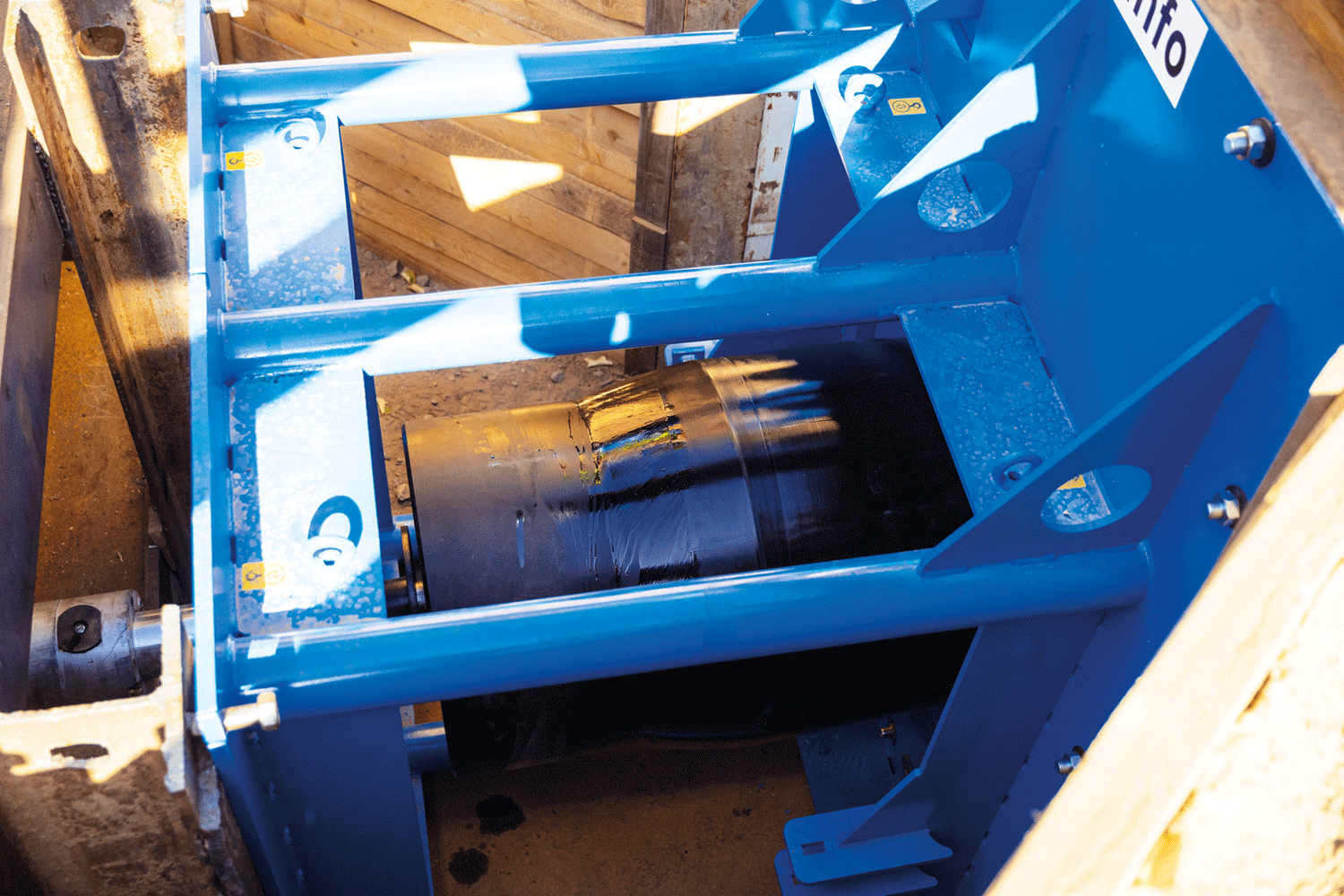

You can imagine that the reduction process only works with powerful and reliable machine technology. The GRUNDOBURST pulling rigs are the perfect solution in many respects. They constantly apply the high tensile forces required for cold forming and drawing in the new pipe up to 2,500 kN depending on the model. The pulling speed and tension can be pre-selected to suit the task. Another key to success is the QuickLock bursting rigs. Their latch connection is so strong that it will not break even under maximum load when the pipe is being pulled in. The project carried out by contractor MRA in Großbeeren near Berlin shows how well the reduction method with the GRUNDOBURST works in practice, even with large dimensions.

The basic principle of the reduction method is based on the possibility of reducing the diameter of the new pipe by hydraulic pulling to such an extent that it can be pulled into the interior of an old pipe of the same diameter. This is done by pulling the pipe string under constant tension through a reduction die which briefly reduces the pipe's cross-section by 10 % to 12 %. When the tension is released, the new pipe expands back to its original diameter and fits tightly against the inner wall of the old pipe. There is no annular space or annular gap, so the old and new pipes now have a "super" close-fit.

You can imagine that the reduction process only works with powerful and reliable machine technology. The GRUNDOBURST pulling rigs are the perfect solution in many respects. They constantly apply the high tensile forces required for cold forming and drawing in the new pipe up to 2,500 kN depending on the model. The pulling speed and tension can be pre-selected to suit the task. Another key to success is the QuickLock bursting rigs. Their latch connection is so strong that it will not break even under maximum load when the pipe is being pulled in. The project carried out by contractor MRA in Großbeeren near Berlin shows how well the reduction method with the GRUNDOBURST works in practice, even with large dimensions.