PROJECT IN FOCUS: CROSSING WITH GRUNDODRILL 28N IN AUSTRALIA

TRACTO

A STRONG PARTNER

WORLDWIDE

A STRONG PARTNER

WORLDWIDE

Brisbane is growing rapidly, with around 2.5 million people living across the city and commuting to work, university or school. More and more people are driving from the suburbs into the city and back. To reduce congestion and CO2 emissions, the city is launching the Brisbane Metro project. An all-electric fleet of vehicles that runs 24 hours a day, without a timetable.

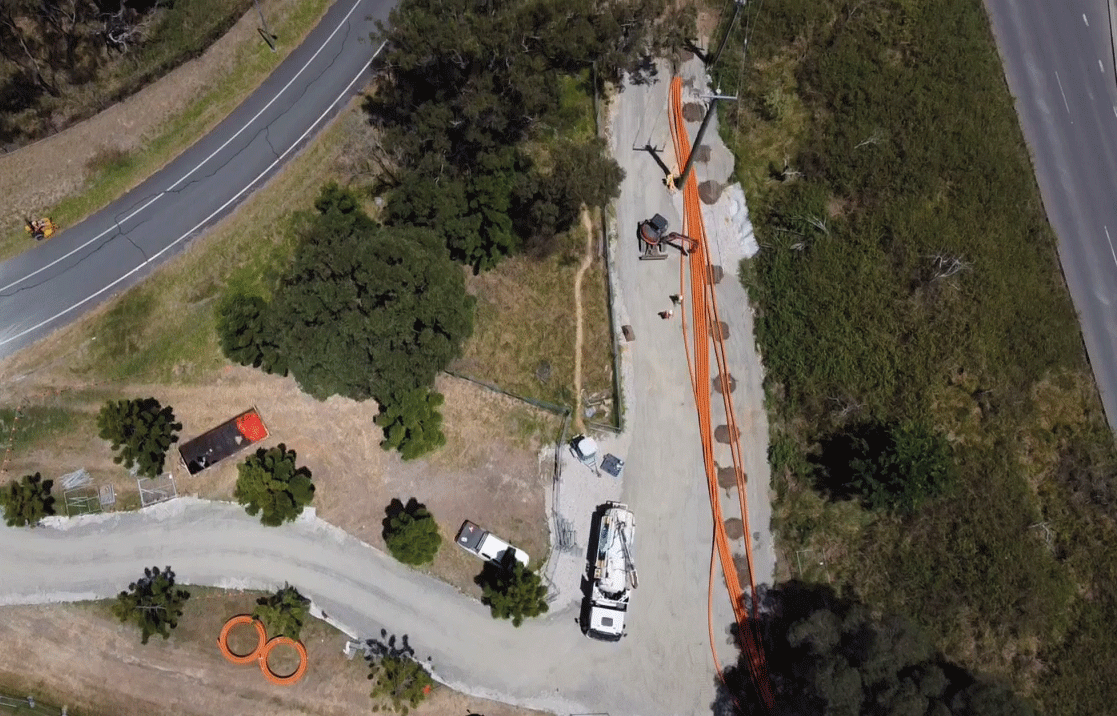

A project like this in a city like Brisbane requires good planning and companies that specialise in working quickly and efficiently with low emissions -a project made for a TRACTO machine. Like the Brisbane Metro project itself, trenchless technologies make a sustainable contribution to environmental and climate protection. TRACTO Australia customer SEQ Trenchless saw this project as an opportunity to use its brand new GRUNDODRILL 28N for the first time in a borehole.

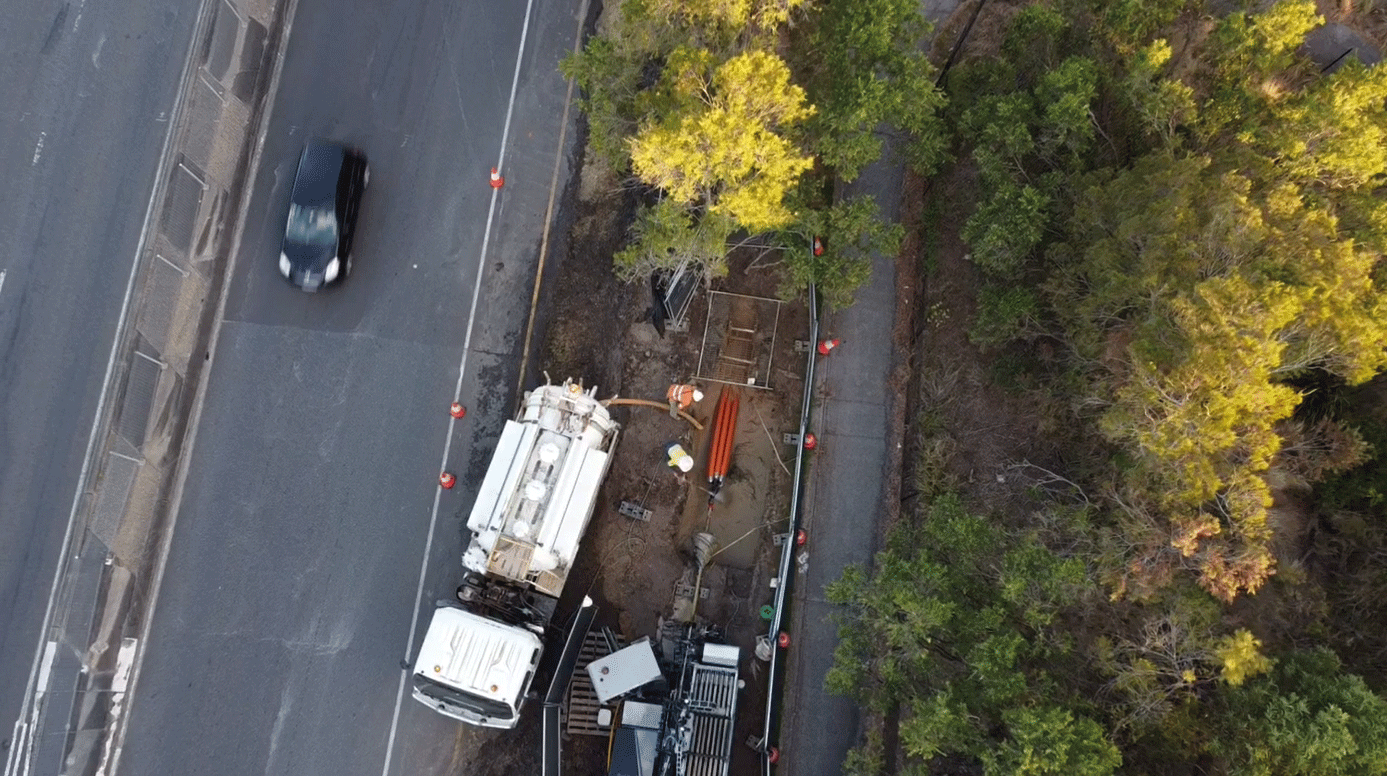

The task in this exciting project was to undercross a busy road for a high-voltage cable bundle with nine cables in sandstone soil with numerous foreign cables. It was clear from the start that the drilling would not be easy, but TRACTO's GRUNDODRILL 28N was exactly the right choice for the narrow construction corridor.

The task in this exciting project was to undercross a busy road for a high-voltage cable bundle with nine cables in sandstone soil with numerous foreign cables. It was clear from the start that the drilling would not be easy, but TRACTO's GRUNDODRILL 28N was exactly the right choice for the narrow construction corridor.

Von Anfang an war klar, dass die Bohrung nicht einfach werden würde, aber der GRUNDODRILL 28N von TRACTO war genau die richtige Wahl für den engen Baukorridor.

Flexibility as a success factor

To ensure the success of the work, SEQ Trenchless had the opportunity to make small changes to the already planned route. For example, the amount of overburden was reduced compared to the original plan to optimise the detection range, and the angle of inclination of the crawler was also adjusted to achieve an optimal result. A good drilling team knows exactly what adjustments are needed to get the most out of the machine and complete the job successfully. Joshua Taylor's team were convinced from the start that they could excel with the GRUNDODRILL 28N.

Flexibility as a success factor

To ensure the success of the work, SEQ Trenchless had the opportunity to make small changes to the already planned route. For example, the amount of overburden was reduced compared to the original plan to optimise the detection range, and the angle of inclination of the crawler was also adjusted to achieve an optimal result. A good drilling team knows exactly what adjustments are needed to get the most out of the machine and complete the job successfully. Joshua Taylor's team were convinced from the start that they could excel with the GRUNDODRILL 28N.

„The GRUNDODRILL 28N impressed us in many ways. The features and performance characteristics have the potential to push the boundaries of what can be achieved with a machine in this class and we were keen to show this in Brisbane„, said Joshua Taylor. „The machine is compact enough to fit into the limited space available, but it promises impressive performance. We were very excited to see if the machine would deliver what it promised,„ he said at the start of the drill.

Compact rig with maximum performance

Drilling of the 208m section began in November 2022, with drilling foreman Shaun Newbigging on site to put the new rig's capabilities to the test. "To ensure a good 'maiden voyage'. We used a mud motor for drilling, which was the best decision given the changing ground conditions", says Shaun Newbiggin.

Compact rig with maximum performance

Drilling of the 208m section began in November 2022, with drilling foreman Shaun Newbigging on site to put the new rig's capabilities to the test. "To ensure a good 'maiden voyage'. We used a mud motor for drilling, which was the best decision given the changing ground conditions", says Shaun Newbiggin.

Daniel Toms, Sales Manager at TRACTO Australia, agrees that the advantages of the GRUNDODRILL 28N open up new opportunities for contractors in the mid-range drill rig sector. "The machine offers everything you need on a jobsite like this. It is incredibly powerful, yet very compact to be used in a very small construction corridor", says Daniel Toms. "With a rod magazine for 288 m of drill pipe, a pump capacity of 650 l/min, a push/pull force of 280 kN and a maximum torque of 11,000 Nm, its compact dimensions are impressive in many ways. This makes it perfect for smaller jobs, but the machine is also powerful when it comes to taking the next step into longer holes and larger diameters in hard rock. According to Toms, it is the intelligent features of the GRUNDODRILL 28N that give contractors even more advantages.

"With a host of automatic features such as semi- and fully-automatic drilling modes, automatic rod change and even automatic rod cleaning, these modern rigs are safer and easier to operate than ever before with a smaller drilling crew", says Toms. "Combined with good data acquisition and transfer capabilities, contractors have all the contractors have all the information they need to not only work efficiently and effectively on this well, but also to plan and improve the next one.

Drilling for the Brisbane Metro Project was a complete success, with the SEQ Trenchless Drilling team's vast experience and the trenchless technology's resource-efficient way of working winning the day.

"With a host of automatic features such as semi- and fully-automatic drilling modes, automatic rod change and even automatic rod cleaning, these modern rigs are safer and easier to operate than ever before with a smaller drilling crew", says Toms. "Combined with good data acquisition and transfer capabilities, contractors have all the contractors have all the information they need to not only work efficiently and effectively on this well, but also to plan and improve the next one.

Drilling for the Brisbane Metro Project was a complete success, with the SEQ Trenchless Drilling team's vast experience and the trenchless technology's resource-efficient way of working winning the day.